How Spark Plug Boot Protectors Can Help Prevent Ignition Failures

ABOVE: New Pro-Boots from Heatshield Products feature patent-pending dual-layer construction to block heat from damaging your engine’s spark plug boots. Pro-Boots feature a closable end that will keep dirt and debris from getting inside the boot, along with preventing hot air buildup as well.

Spark plug boots protectors go a long way in preventing unexpected and potentially damaging ignition failures. Spark plug boots live in one of the most abusive areas on an engine when it comes to heat exposure. Usually located right next to the exhaust manifolds or headers, the boots are exposed to constant high ambient temperatures that wear on the boots and will lead to their eventual failure along with the spark plug wire in the boot. In addition, as the boot gets hotter and stays hot, that heat soaks the spark plug wire inside the boot, which increases electrical resistance for the energy going through the wire. This increased resistance reduces the amount of spark energy that reaches the plug, due to parasitic loss from the heated spark plug wire.

The main functions of spark plug boot protectors are:

- Protect spark plug boots from excessive and damaging heat exposure

- Ensure against misfires and ignition failure due to a heat damaged or melted spark plug boot

- Prevent heat soak of spark plug boot and wire that increases electrical resistance and reduces spark energy reaching the plug

ABOVE: Traditional spark plug boot protectors are made from fiberglass cloth that provide some protection from heat but don’t offer any abrasion resistance or real protection against underhood exposure to oil, solvents or corrosives. Traiditonal boot protectors also have an open end that allows dirt, debris and heat to be trapped inside the boot that can increase damage and negate any heat protection they provide. Pro-Boots feature a closable end that keeps all the harmful elements out, while the dual-layer construction using LavaTM outer layer and Tac-Armor inner layer provides protection from those elements along with abrasion resistance.

ABOVE: Typical spark plug boot protectors feature a non-sealable end that allows dirt and debris to build up inside the protector. It also allows for the formation of a hot air pocket inside the protector that can heat-soak the boot can pretty much negate the protection it’s supposed to provide. Pro-BootsTM sealable end eliminate that problem to provide total protection.

Spark Plug Heat Shield Protection

Heatshield Products’ new Pro-BootsTM were designed to provide the best protection possible for spark plug boots located next to exhaust manifolds or headers. One point where typical spark plug boot protectors are vulnerable is on the open end. Research and input from users has shown the open end allows dirt and debris to be trapped around the boot and cause issues, especially when removing the wires for maintenance. In addition, the open end can cause heat to be trapped inside the boot. This trapped heat continues to soak the spark plug boot covers in high-temperature ambient heat that accelerates wear and damage to the boot, while also causing an increase in electrical resistance that reduces spark energy.

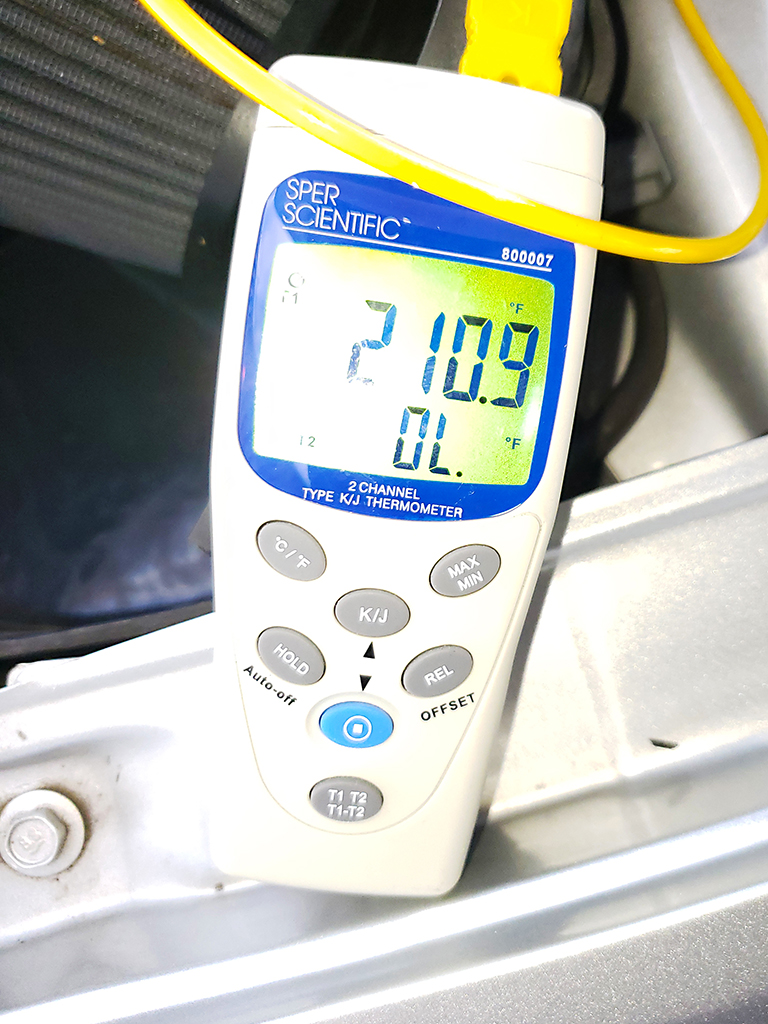

ABOVE: An unprotected spark plug boot is subject to a constant amount of high-temperature ambient heat. As an example, we used this 2012 Camaro SS equipped with headers to show exactly how hot an unprotected spakr plug boot can get next to tubular exhaust headers.

ABOVE: Using our contact probe, with the car at operating temperature and a 15-minute drive time, the spark plug boot measured 210.9 degrees F. That’s the kind of a heat a spark plug boot will see constantly every day if left unprotected. And the more power a vehicle makes, the more/higher-temp heat that’s generated to soak the spark plug boot.

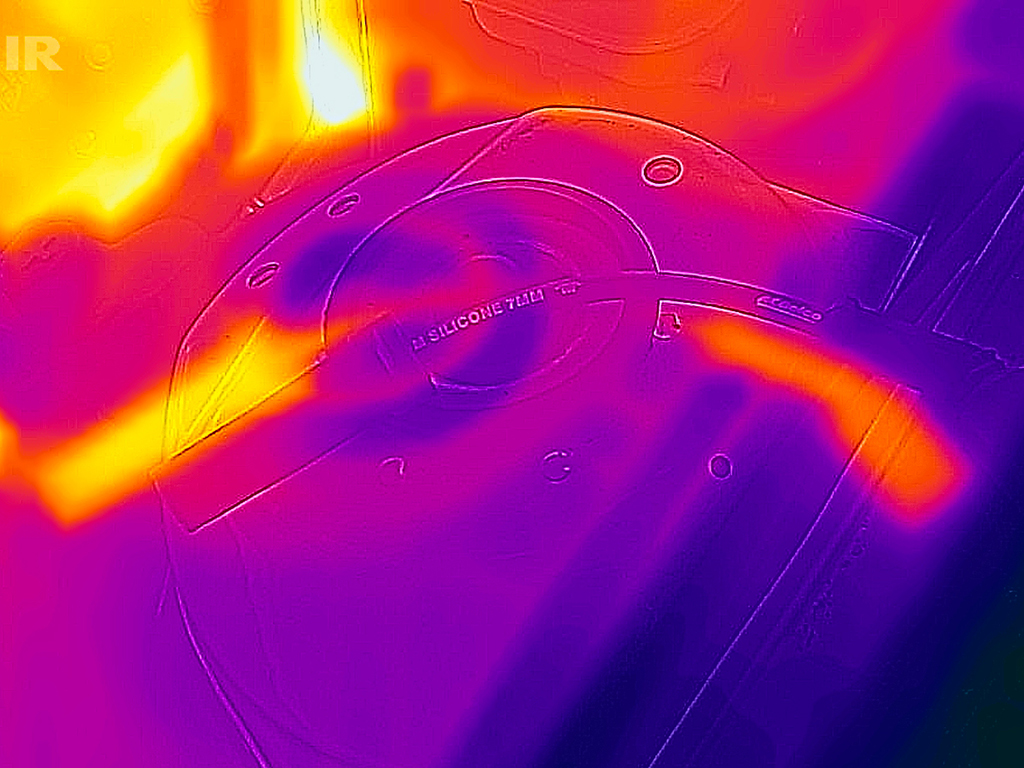

ABOVE: To further illustrate the heat situation, we removed the spark plug wire and took a picture using our FLIR One forward-looking-infrared camera. You can see even off the engine and no spark energy running through the wire the boots stay particularly hot, especially the plug end of the wire.

A feature of the new Pro-Boot is a closable end using high-temp hook & loop fastening so you can reopen the Pro-Boot and remove it if necessary. This closable end helps keep dirt and debris out while also preventing a pocket of heat from building inside the boot protector. Pro-Boot uses an outer layer of Heatshield Products specially-formulated Lava thermal barrier material, with a liner made from the all-new Tac Armor material. This combination of materials not only provides superior thermal protection, but also a 25 percent stronger construction than traditional fiberglass spark plug boot protectors. Besides protection from heat and chemical exposure, the outer LavaTM fiber layer provides some abrasion resistance/protection.

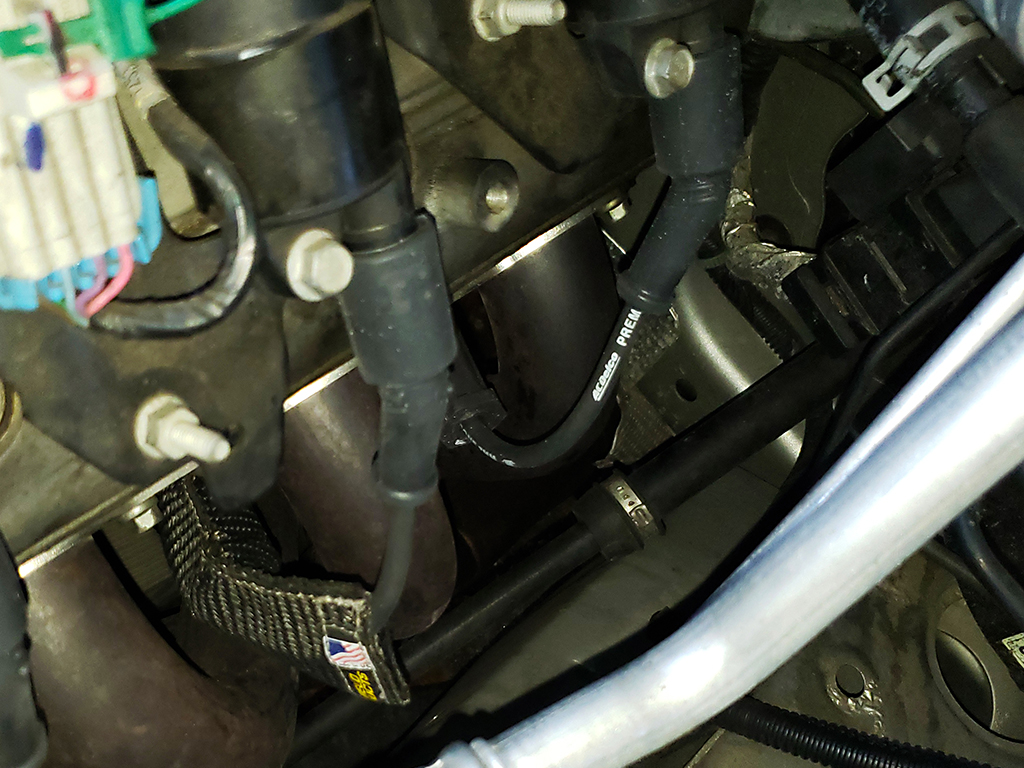

ABOVE: Pro-Boots are a must whether you have cast-iron exhaust manifolds or tubular exhaust headers. They install in seconds and provide complete protection against heat, exposure to underhood elements, and even abrasion resistance should that become an issue.

Need a heat shield protector sleeve? Pro-Boots are available in packs of 2 or 8, and either Lava Fiber finish or Stealth Black.