Protecting Your Spark Plug Boots

Whether it’s a race car or a street car, protecting your spark plug boots from heat exposure and damage can go a long way to not only prevent heat-related ignition issues, but to ensure that you get the most life out of your spark plug boots and wires. In our last blog we showed the difference between our new Pro-BootsTM model versus an unshielded spark plug boot. But what about Pro-Boots versus a factory spark plug boot heat shield?

Just because the OEM manufacturer calls something a heat shield doesn’t mean the part is actually as effective as a heat shield. From the factory, GM LS- and LT-series engines come equipped with a simple, stamped aluminum spark plug boot heat shield. These shields are marginally effective, with the downside being that once they’re heat-saturated, the spark plug boots inside the shield will also become heated and suffer the negative effects from cooking inside the shield. A better solution is required, especially on high-performance street and race cars using tubular exhaust headers that generate more heat in close proximity to the spark plug boots and wires.

To see what kind of a difference the new Pro-Boots make against the factory shields, we borrowed a friend’s bone stock C7 Corvette. With some Pro-Boots in hand along with our heat measurement tools, we went to work for some testing. Follow our photos to see what we found.

ABOVE: All LS- and LT-series engines share the same ignition wire setup with the same metal spark plug boot heat shields. In a vehicle like the C7 Corvette, there is much less open space near the engine than a truck. These tighter confines serve to increase the amount of heat the spark plug wires/boots are exposed to compared with a truck/SUV or even the Camaro.

ABOVE: Once we got the Corvette up to operating temperature, we started taking some heat readings. Using a direct contact probe, we measured how hot the factory spark plug boot shield got once the engine was up to normal operating temperature, while the engine was still running.

ABOVE: The factory heat shield measured 210.2 degrees F, and this was without any heat soak as seen with continual operation. Since the factory shield is in direct contact with the spark plug boot, and its aluminum construction makes it a conductor of heat, this means that heat is being transferred to the boot. While silicone isn’t a good conductor of heat, it can still be heated up to temperatures that cause the boot to wear and break down. It also means that as the boot heats, electrical resistance in the spark plug wire increases. As resistance goes up, the amount of spark energy reaching the spark plug for ignition decreases, hurting performance. Using a Pro-BootTM spark plug insulator will greatly help manage this heat and resistance.

ABOVE: The factory spark plug boot heat shield is a stamped aluminum piece that slips directly over the spark plug boot and remains in direct contact with the boot. Being made of aluminum, the shield conducts heat energy like any aluminum-based item. Since it is in direct contact with the spark plug boot, that heat can unfortunately be transferred to the boot.

ABOVE: Heatshield Products new Pro-BootTM spark plug boot heat shields are designed from HP’s proprietary and specially formulated LavaTM thermal barrier material made from volcanic rock-based fibers. Unlike the aluminum the factory heat shields are made from, LavaTM material doesn’t conduct thermal energy nearly as much. This means less heat gets through the barrier that can have an affect on the sparkplug boot. Pro-BootsTM can withstand up to 1200 degrees F of constant heat, while also being chemical and acid resistant. They also will not conduct electrical energy as well, unlike the factory aluminum shields, making them a fantastic choice as both a heat shield and a spark plug boot wire protector.

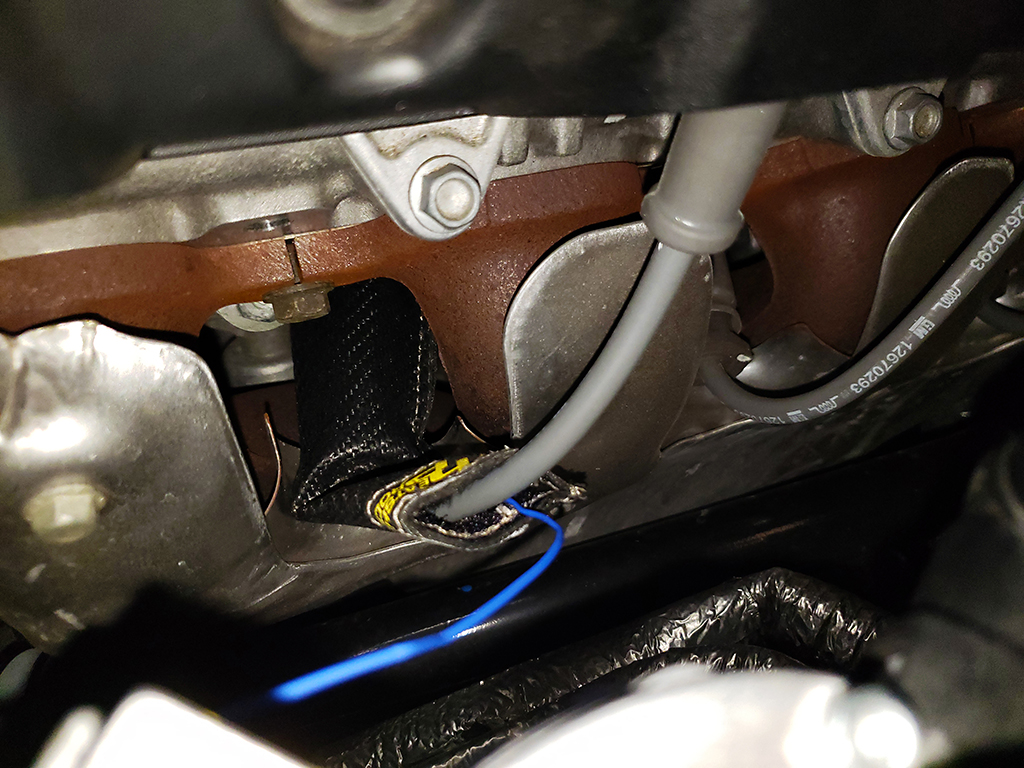

ABOVE: An added feature of the Pro-BootTM is a closeable end that allows for the heat shield to be sealed. This prevents dirt and debris from accumulating inside the Pro-Boot, which can cause degradation of the spark plug boot like an abrasive activated by engine vibration. It also prevents a pocket of heated air from forming and creating a mini-oven effect inside the shield. This effect is a weakness in standard spark plug boot heat shields that have a non-closeable end. The blue wire coming out of the Pro-Boot in the photo is a thermal probe that lets us measure the temperature inside the Pro-Boot. We also rigged up a probe inside the factory heat shield on the neighboring cylinder for comparison.

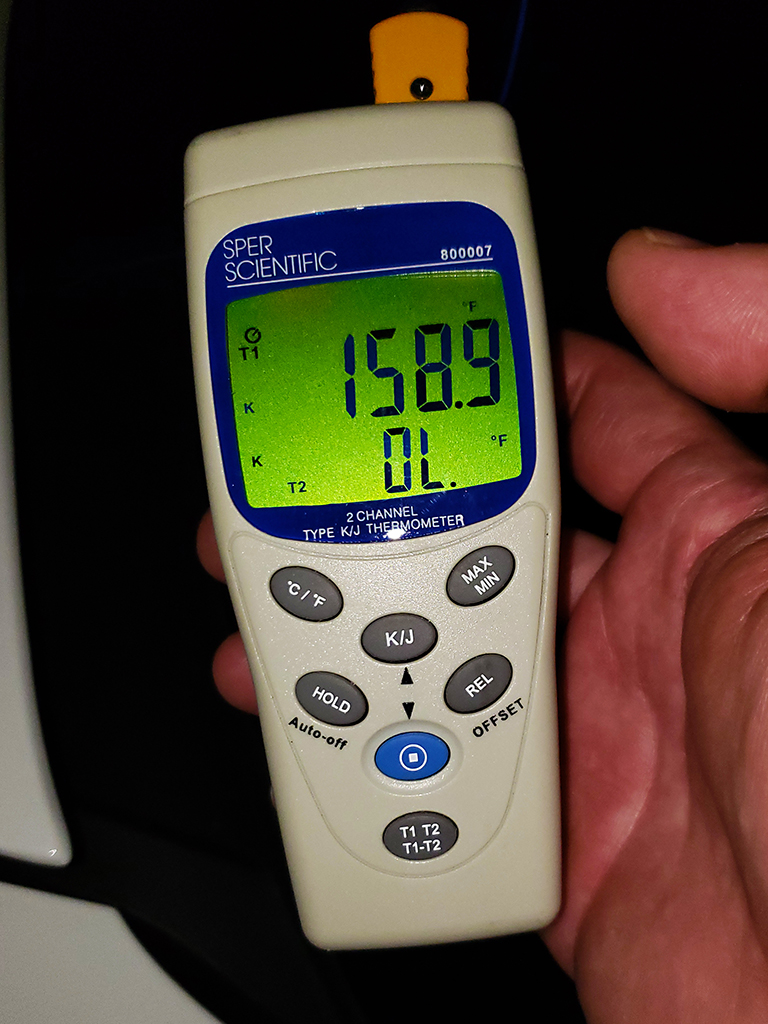

ABOVE: With Pro-BootTM installed, we measured a temperature of 158.9 inside the heat shield. From the probe inside the factory heat shield, we measured 212.1 degrees F. That’s a reduction of about 54 degrees F, a huge difference that provides much less damage and performance-affecting heat that the spark plug boot would be exposed to.