Exhaust Heat Shield Kit

![]() Personalized Custom Solutions

Personalized Custom Solutions

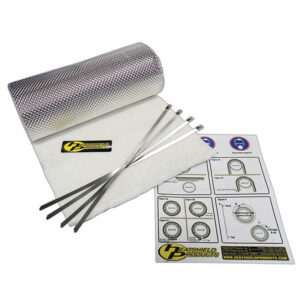

Exhaust Heat Shield Kit

Exhaust pipe heat shield kits are an easy way to keep your car cool and protect vital components from heat damage. Built with the same high-performance material as our Heatshield Armor, these kits come with added Thermal Ties for convenient installation.

WARNING: Cancer and Reproductive harm – www.P65Warnings.ca.gov

Protect your interior, mufflers, and exhaust system components with one of the toughest kits on the market with our Heatshield Armor® exhaust heat shield kit. This heavy-duty set includes everything you need to install hot pipe insulation within minutes and comes in several varying thicknesses for everything from regular driving to racing applications.

Our Heatshield Armor® exhaust heat shield kit is designed for the most extreme heat with a 4 mil thick armor layer that can easily be cleaned after installation and is resistant to the elements for a longer lifespan. In fact, this thick armor layer can reduce radiant heat by 70%!

The inner bio-soluble silica insulation allows this automotive heat shield to withstand up to 1800°F continuous and 2200°F intermittent—making this flexible shield ideal for using directly on headers, turbo manifolds, downpipes, mufflers, genset, exhaust pipes, and DPF (depending on your state regulations). For forced induction and racing, we recommend our thicker 1/2” Heatshield Armor.

No, Heatshield Armor will stop the most heat from radiating up from the pipe, period. The Heatshield Armor kits sit directly on the exhaust. This allows less heat to escape compared to those heat shield that clamp on with the stand offs. You can trim it to cover just the top half or cover three quarters of the pipe instead of using a stand off heat shield, this way you trap most of the heat at the source, you don’t have an air gap and try to indirectly divert heat, direct diversion works better. Physics doesn’t lie, the most efficient way is to manage heat directly at the source.

No, Special tools are not needed. A good pair of scissors, a utility knife, and a pair of needle nose pliers are all that is need to install. Just use what you have in your tool box.

![]() Personalized Custom Solutions

Personalized Custom Solutions

Simple installation – in minutes