Trusted Since 1985 – Proven Protection, Maximum Heat Reflection!

![]() Personalized Custom Solutions

Personalized Custom Solutions

Trusted Since 1985 – Proven Protection, Maximum Heat Reflection!

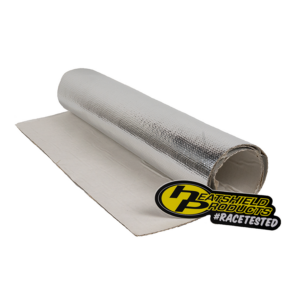

Good old reliable heat shield material used for decades! Aluminized fiberglass that has been around since we started in 1985

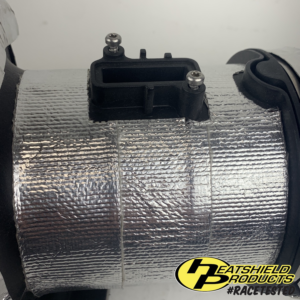

Keep your cool with Heatshield Mat! When installed with 1 inch of airspace and proper airflow, it reflects up to 90% of radiant heat. It handles 1,100°F radiant and 450°F direct heat, making it ideal for shielding floor pans, mufflers, catalytic converters, DPFs, and exhaust systems. Face the aluminized side toward the heat source for best results. Use it on firewalls to block engine heat or apply it to metal and plastic airboxes to reduce intake temperatures. Available with high-temp peel-and-stick adhesive for easy installation. Not recommended for rough or unfinished fiberglass or carbon fiber surfaces. Bulk rolls also available.

The peel and stick version of HP Heatshield Mat does not stick well to rough surfaces. You should use the non-adhesive version and use a spray adhesive like 3M Super Trim Adhesive or Super 77. The spray adhesives can fill in the surface inconsistencies of unfinished fiberglass or carbon better than peel-and-stick adhesives.

![]() Personalized Custom Solutions

Personalized Custom Solutions

Simple installation – in minutes