There are a lot of myths, malarkey and horse manure out there when it comes to exhaust wrap. The biggest pile is that exhaust wrap destroys your headers. This is a misconception that scares people away from using exhaust wrap to increase performance. When you wrap exhaust headers, more heat stays in the header pipes—which is what you want.

Where the misconception comes into play is with what happens after the wrap is on. There are a multitude of headers out there and therefore a variety of alloys for tube material. Metal alloys have a minimum and maximum temperature rating for what they can withstand. Extreme cold has major effects on metal just like extreme heat does. That’s why aircraft aluminum is designed to withstand extreme cold way more than extreme heat. An aircraft spends most of its time flying at altitude, where the temperatures are much colder than on the ground.

The alloy used for header pipes has to be capable of withstanding the heat being generated by the engine exhaust. When you put exhaust wrap on headers, that keeps more of that heat inside the pipes, which raises the sustained temperature. But cheap/substandard headers use alloys that aren’t capable of handling that increased heat and will become thin and brittle, then eventually crumble. That’s not the fault of the exhaust wrap retaining heat, but rather an inferior header.

Another area of misconception has to do with condensation. Steve Heye, Heatshield Products Head Peon and son of co-founder, Bruce Heye, explains his thoughts on that one and more.

“A lot of people say wraps hold moisture in from condensation and cause rust. That’s a load of crap. I have never understood the condensation argument. When was the last time you saw condensation on a hot coffee cup? When have you seen it on a glass of hot tea?

“I have personally seen it on a cold drink with ice, I’ve seen it on glass cups, plastic cups, ceramic cups. Condensation is formed when water vapor cools. When on a glass, or on your window, or on your car, or from a cold air mass (like fog), the water vapor in the air cools enough to form condensation. A hot exhaust pipe does not cool air – it heats it. Condensation INSIDE the exhaust pipe definitely happens. That is a byproduct of a properly working gasoline engine.”

The combustion of octane follows this reaction:

Gasoline Exhaust

2 C8H18 + 25 O2 → 16 CO2 + 18 H2O

“Heatshield Products makes very large, very thick exhaust insulation jackets for off-shore platforms, boats, ships, etc. The marine industry (keep in mind here marine, where there is more water vapor in the air – salt water at that) never worries about trapping condensation on the outside of a pipe. In many larger vessels, the U.S. Coast Guard requires insulation on these exhaust systems.

“I immediately block people out who talk about condensation forming on the outside of a warm exhaust pipe. Their brains clearly do not occupy space in the same world where the laws of physics and chemistry exist.

All that being said, some people are completely uncomfortable with using an exhaust wrap. I don’t take that personally; we are totally fine with that. If it is a thin-wall exhaust system, not allowing some heat to escape the pipe might cause some fatigue. That is why we have created our Armor™ series of insulation. For you, this might be the best hybrid to put your mind at ease instead of using a wrap. Yet like a wrap, you can drastically outperform the hot side temperature of a coating.

“We are not anti-coating here. In fact, if you have the budget to do both, we encourage it. Coatings are great. On some thin-wall exhaust systems, they can greatly improve the lifespan and reduce some heat. Then you can go over the top with the Armor series and dominate the inferno.”

If you’ve got headers and want to wrap them but are unsure whether they can handle the extra heat, contact your header manufacturer to find out what their exhaust temperature ratings.

By keeping more heat in the headers, both exhaust gas temperature (EGT) and exhaust gas velocity increase. You can read more about EGT in our recent blog, but, simply put, the increased EGT leads to increased gas velocities, which helps exhaust scavenging so that more exhaust gas can be expelled from the combustion chamber before the intake stroke begins. For turbo cars, increased EGT helps to reduce turbo lag and allows the turbo to spool even higher, creating more boost. Also, keeping more heat in the exhaust header helps the oxygen sensor get more accurate readings of the exhaust, translating into better adjustments by the computer for optimal air/fuel ratio.

Another big benefit is decreased underhood temperatures, which reduces wear and tear on underhood components and reduces the amount of heat being radiated by the headers; that heat could negatively affect performance of components and systems near the headers. But the biggest benefit is the lower intake air temperatures (IATs) that result from cutting underhood heat. As the temperature of air drops, it becomes more dense. Denser air allows for the engine to make more horsepower, while hotter/thinner air makes for the opposite. Every degree that IATs can be lowered is worth more horsepower.

ABOVE: On an LS engine, the header passes right by the factory oil cooler. Wrapping the header reduces the amount of heat around the cooler, so it has less heat to dissipate while cooling the engine oil.

Installing exhaust wrap isn’t hard, but does require a bit of patience, a few basic tools and a Heatshield Products Lava Exhaust Wrap kit. Follow along as we show you how to do it and the results we got.

ABOVE: The Lava Exhaust Wrap kit comes with everything you need to do one full-length header or a pair of shorty headers. The kit includes a small and large HP Thermal-Ties to secure the wrap. Lava Wrap is made from Heatshield Products proprietary volcanic rock-based thermal-barrier material, but it can still cause a bit of itching to bare skin, so we recommend wearing gloves while working with it.

ABOVE: Another thing to have on hand when installing exhaust wrap is high-temp clear spray paint. After cutting the wrap, spray the end with the high-temp clear spray paint to prevent the wrap from fraying. After the wrap is installed, spray it again for the same reason.

ABOVE: On most headers there’s a tight space where two tubes will be very close together. A small screwdriver can be used to gently pry the pipes slightly apart so that the wrap can pass through and around. Some exhaust wraps must be soaked in water before installation. Lava Wrap needs only a spritz of water from a spray bottle to lightly wet the wrap.

ABOVE: A sharp razor blade is good for trimming Lava Wrap once you finish wrapping the pipe. For general cutting, a good pair of heavy-duty scissors will work. Once you make the cut, spray the end with high-temp clear spray paint to prevent the ends from fraying.

ABOVE: When wrapping the header, you want part of each loop to overlap the previous one.

ABOVE: The large HP Thermal-Tie should be used for securing Lava Wrap on the collector.

ABOVE: Here’s what the finished headers look like with Lava Wrap. The specially formulated fibers are one of the best features, because they remain flexible even after numerous heat cycles. That means if you ever have to unwrap the header, you can re-wrap easily and without a loss of effectiveness.

ABOVE: Before installing the wrap we took two sets of temperature readings. This is the ambient underhood reading, where we saw a temp of 147.3 degrees F.

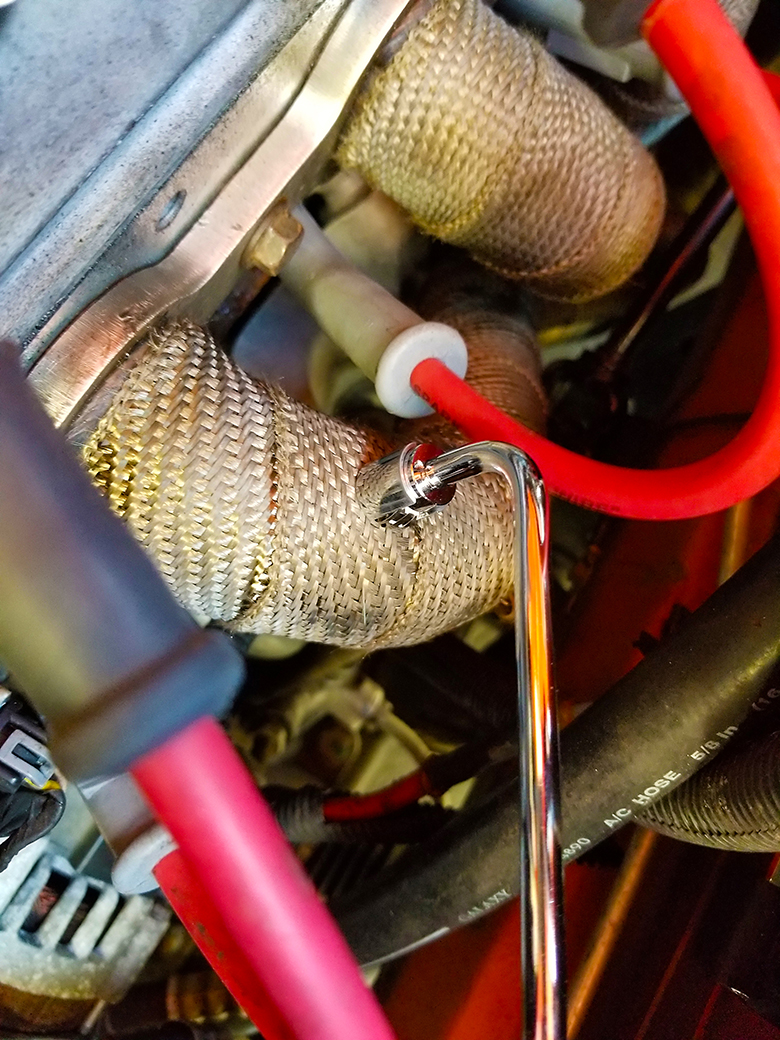

ABOVE: To measure direct temperatures of the unwrapped and wrapped exhaust headers, we used a calibrated, direct-contact temperature probe.

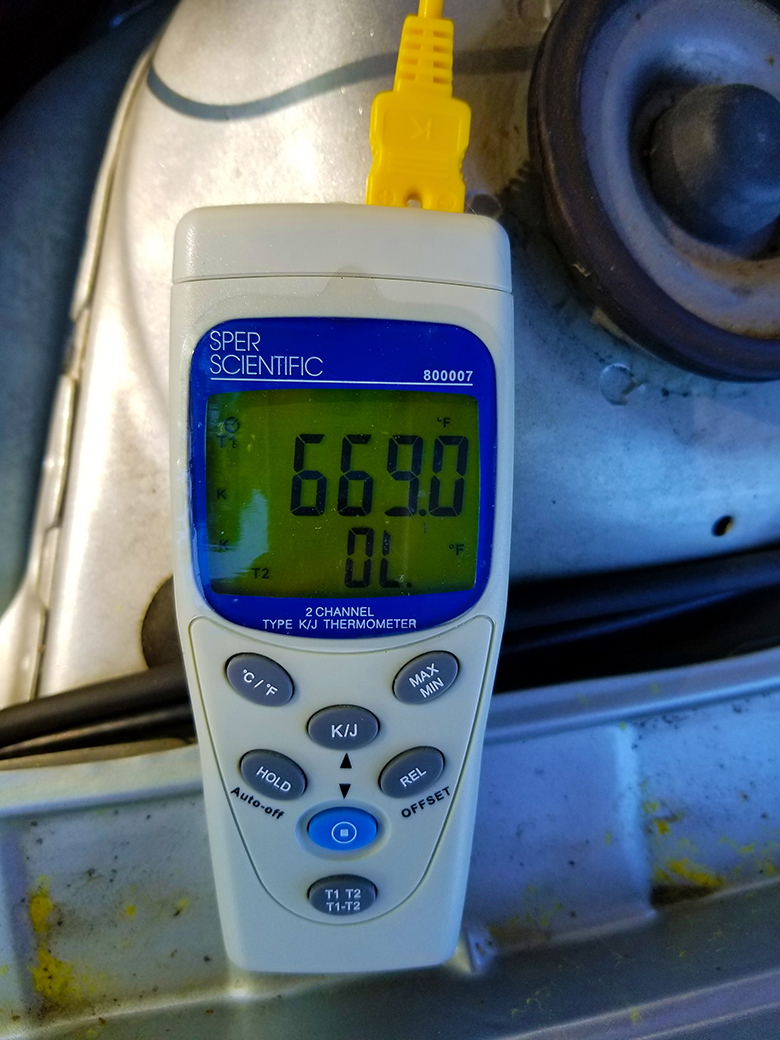

ABOVE: We had a 2012 Camaro with modifications similar to our project car’s for comparison testing, but without Lava Wrap on its long-tube headers. We measured chassis dyno horsepower and placed the probe in direct contact with the header pipe, about 3-4 inches away from the header flange where it bolts to the cylinder head and measured 669 degrees F. Moving to each cylinder on both sides, we saw temperature readings within 10 degrees of this measurement.

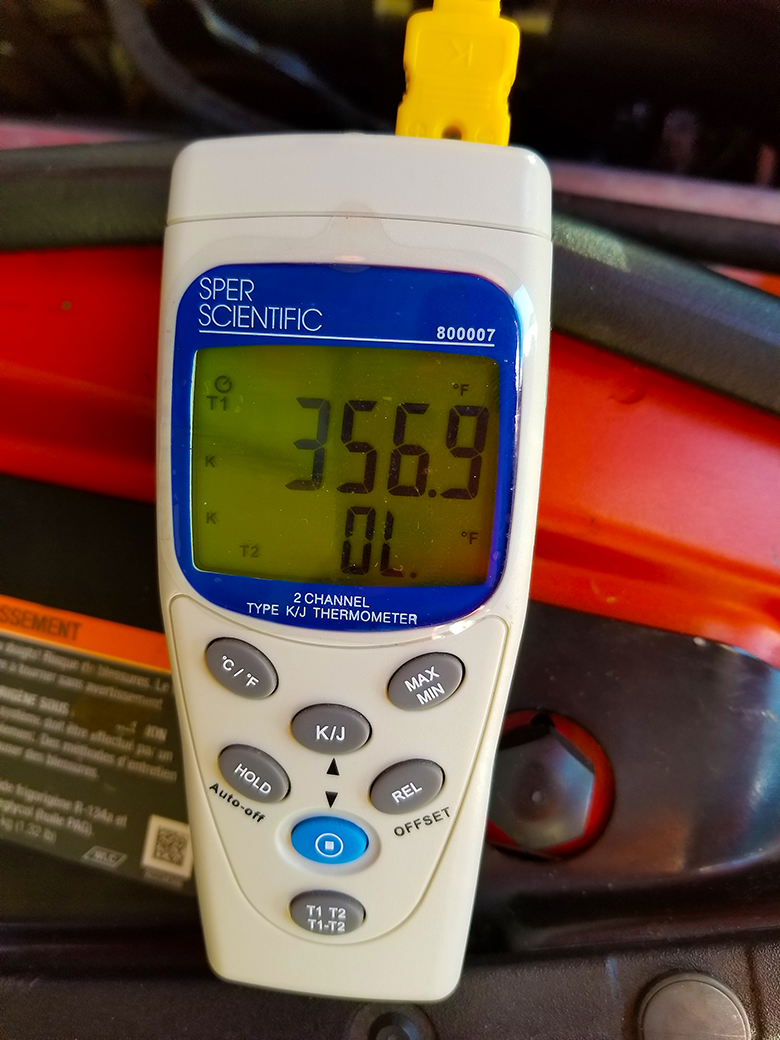

ABOVE: We measured the exhaust header wrapped with Lava Wrap in the same manner as before and saw readings close to our first measurement of 356.9 degrees F. That’s a 313-degree drop from the unwrapped header. That’s more than 300 degrees less heat radiating into the engine compartment. As a bonus, it also means while working around a hot header if you happen to touch it or brush against it, you have a precious few seconds to avoid searing your flesh.

ABOVE: After taking header readings, we closed the hood and drove the car around for about 10 minutes at operating temperature, then came back to the shop to check ambient temperature readings. Thanks to the Lava Wrap–encased headers, underhood ambient temperature dropped to 136.5 degrees F, a 10.8-degree drop from our baseline of 147.3 degrees F. Those lower underhood temps will help to reduce intake air temperatures and heat exposure to all underhood components.