Lava Turbo Shield And Exhaust Wrap Install With Before/After Comparison

An unshielded/uninsulated turbo and its supporting systems represent horsepower being left on the table, and an exhaust wrap install can easily help you fix this. In addition to its wasted potential, an uninsulated turbo system will also have negative effects on reliability as the constant high underhood temperatures accelerate wear on underhood components.

The real head scratcher with seeing an uninsulated turbocharger setup is how easy it is to insulate the system, keep more heat in it and enjoy the benefits it provides. From cost to installation, there are no insurmountable or even remotely difficult obstacles standing in the way of placing a turbo heat insulating turbo shield and exhaust wrap install for a fully insulated system. And that’s where Heatshield Products steps in.

Insulating Your Turbo Shield Provides These Benefits:

- Increases exhaust gas temperatures (EGTs) which increases exhaust gas velocity (EGV) and helps to reduce turbo lag, turbo chatter and decrease the amount of time it takes for the turbo to reach full boost output

- Significantly reduce the amount of radiant heat generated underhood by the turbo system

- Through reduced radiant heat, reduced heat exposure for underhood components which helps to improve component consistency, reliability and operational life

- Makes it easier to work under hood even when exhaust system is still hot after shutdown

These benefits are even more crucial and noticeable with late model vehicles today where the engine compartments are much tighter and have less airflow through them. A great example are the 1994-2004 SN95/New Edge Mustangs. Especially with the later models with modular 2V and 4V V8s where the engine fills up a lot of the space between the shock towers and the exhaust system is in close proximity to a lot of stuff. Even more so when a turbo system is added to the equation.

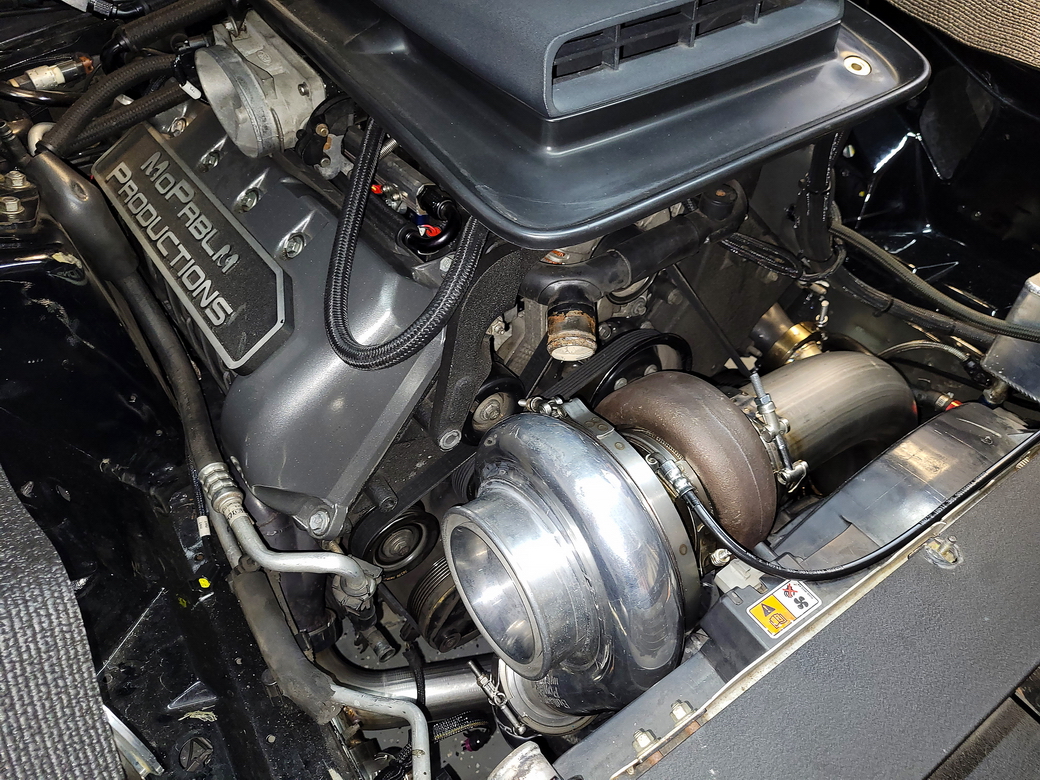

We recently had a chance to work with Kyle Miller and his 2004 Mustang Mach 1 to insulate the turbo system after he installed a bigger turbo on the built 4V/DOHC 4.6 in the car. The goal is for the car to consistently be in the 8-second E/T (elapsed time) range while also being fully reliable for legitimate street driving. Part of this is insulating the new turbo system for the benefits listed above.

Installation Of Lava Heat Insulating Turbo Shield And Exhaust Wrap

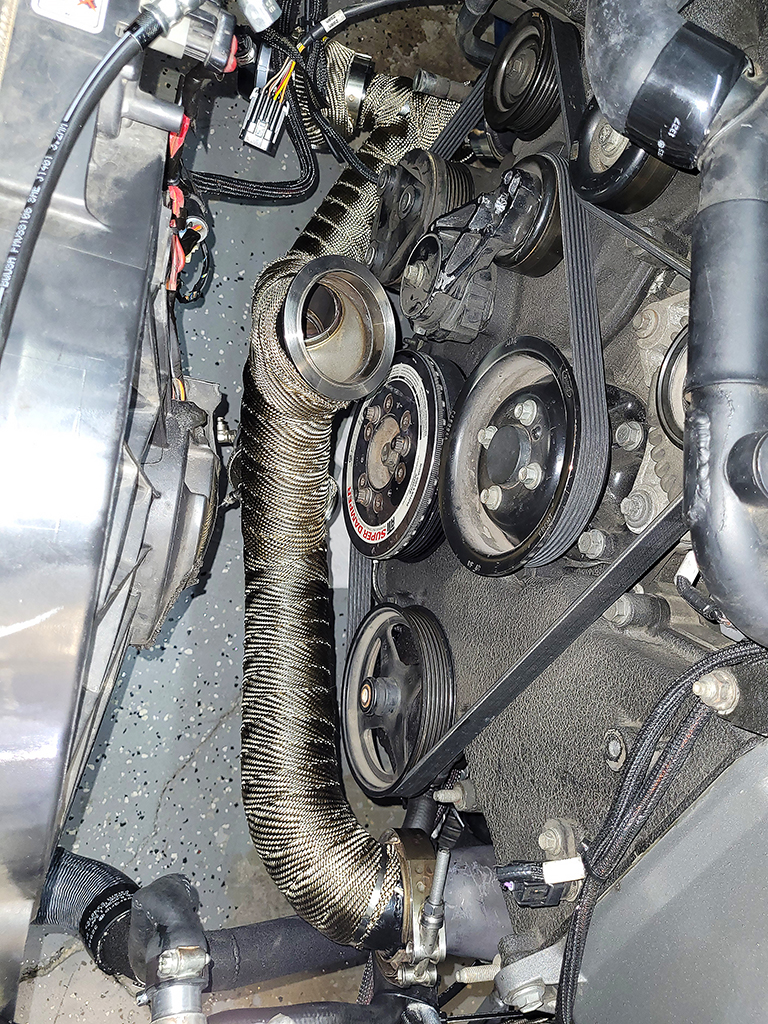

A turbocharger is a great way to increase horsepower and torque, but a turbo system adds a major radiant heat source to the engine compartment. With 1994-2004 SN95/New Edge Mustangs, the tight confines of the engine compartment (especially with a 2v or 4V modular V8 in place) make insulating the turbo exhaust piping and hot side of the turbo a necessity.

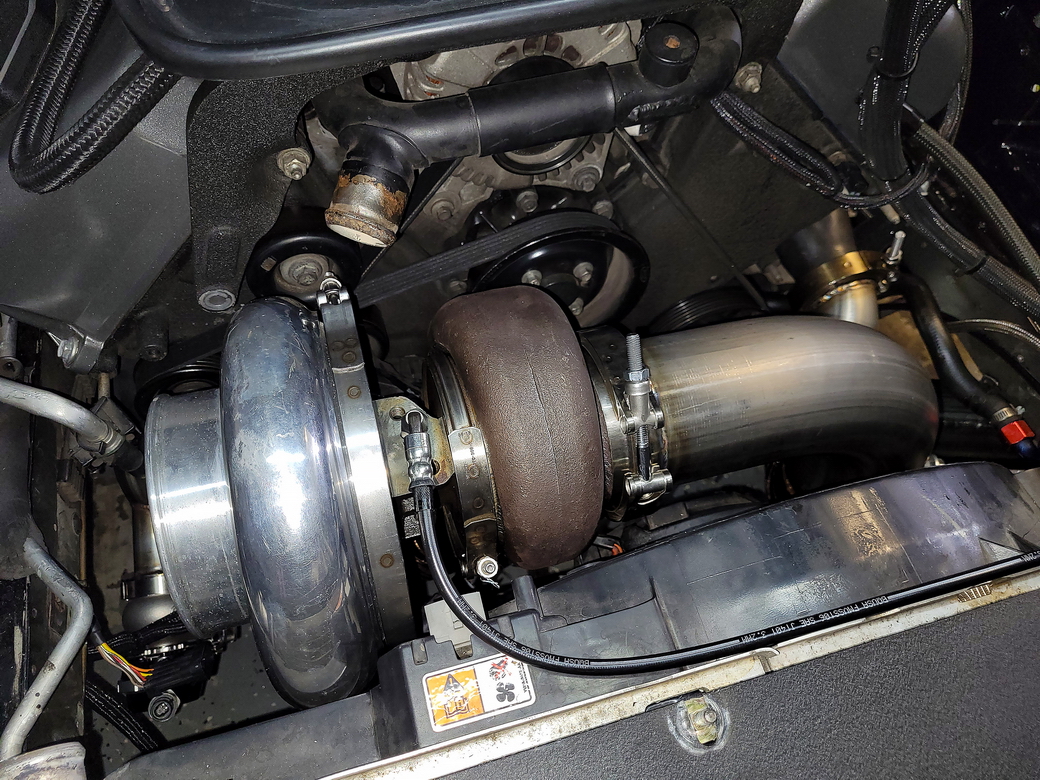

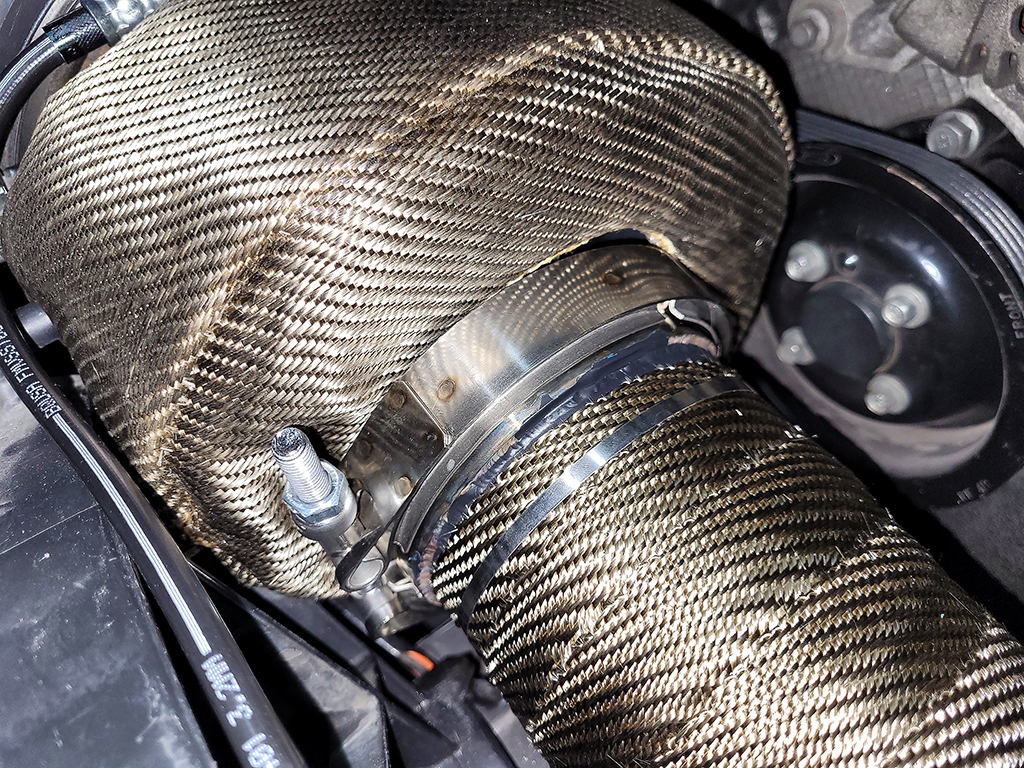

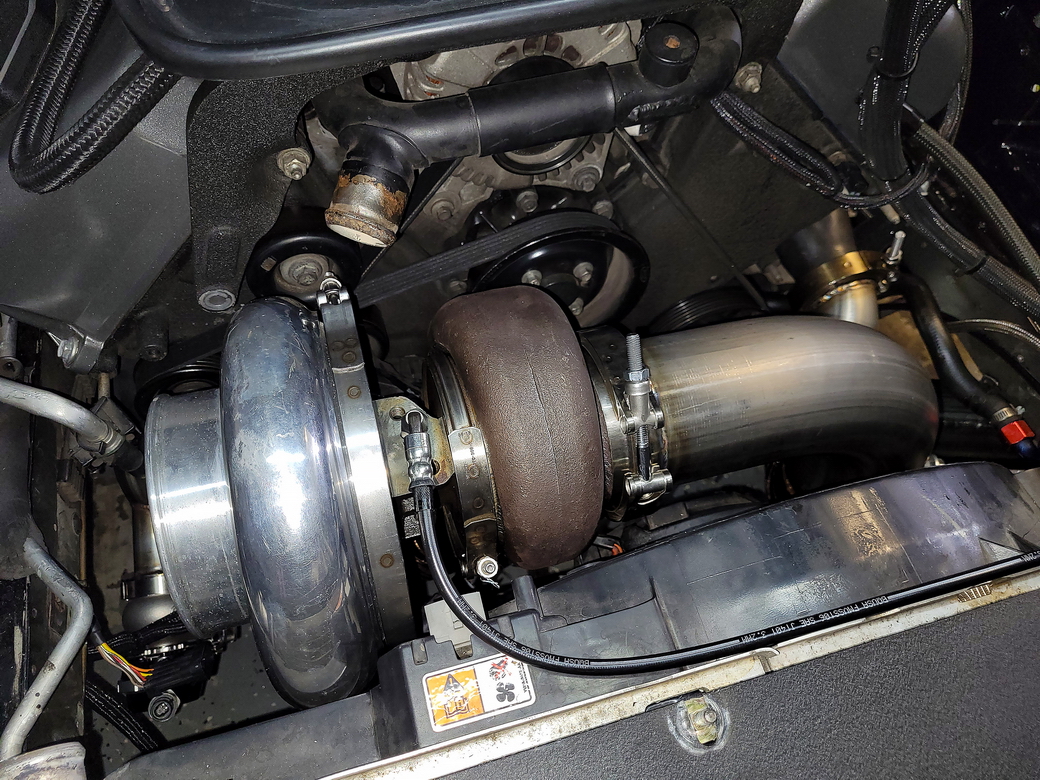

The turbocharger is a Bullseye 83/96 compressor with dual wastegates. Much larger than the previous turbo, this means even more heat underhood and with the front mount right by the radiator/fan assembly exposing a lot of components to this heat. There was already an issue with the old turbo downpipe where it had melted part of the radiator fan.

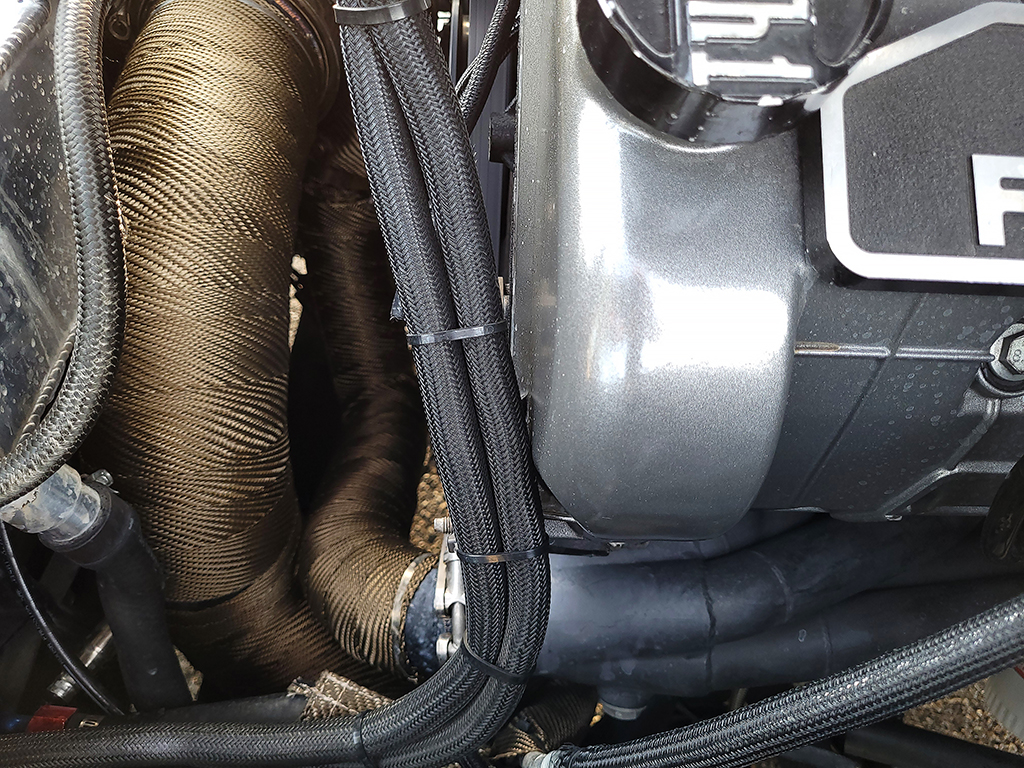

It’s a tight fit for the feed and down pipes, which are also major radiant heat sources if left uninsulated. Insulating these pipes helps to increase exhaust gas temperature (EGT) which increases exhaust gas velocity (EGV). This improves turbo performance by decreasing spool time, turbo lag and turbo chatter. It also helps to greatly reduce the amount of heat components near the pipes are exposed to. Such long term heat exposure can negatively affect component function and reliability while also shortening component lifespan.

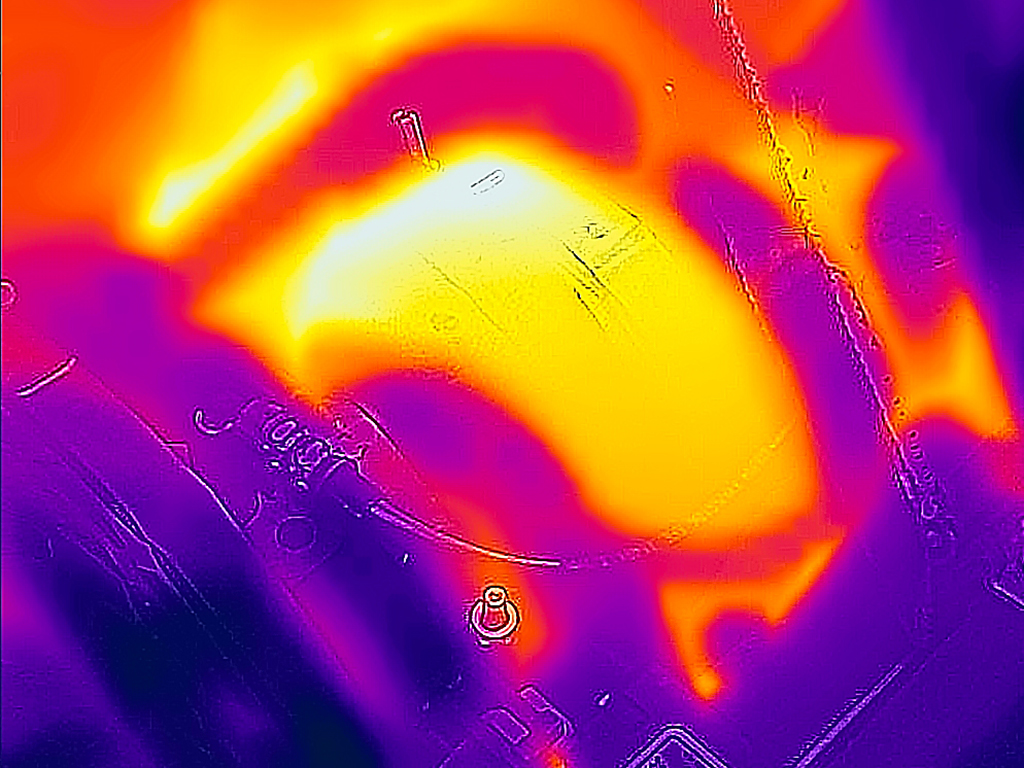

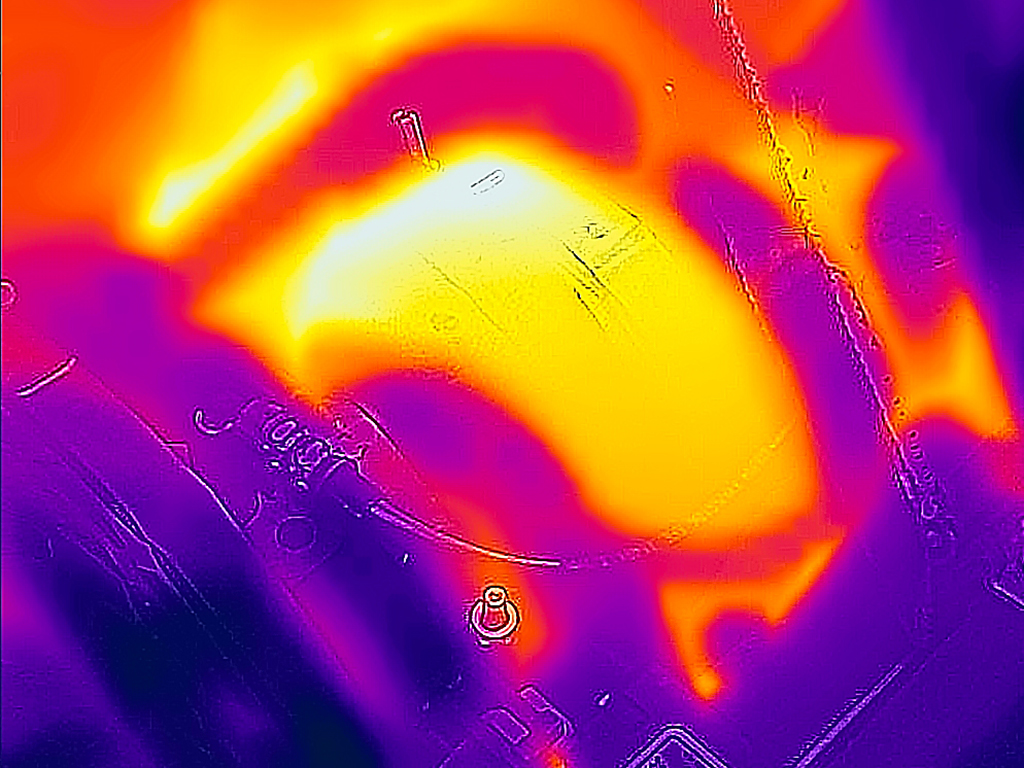

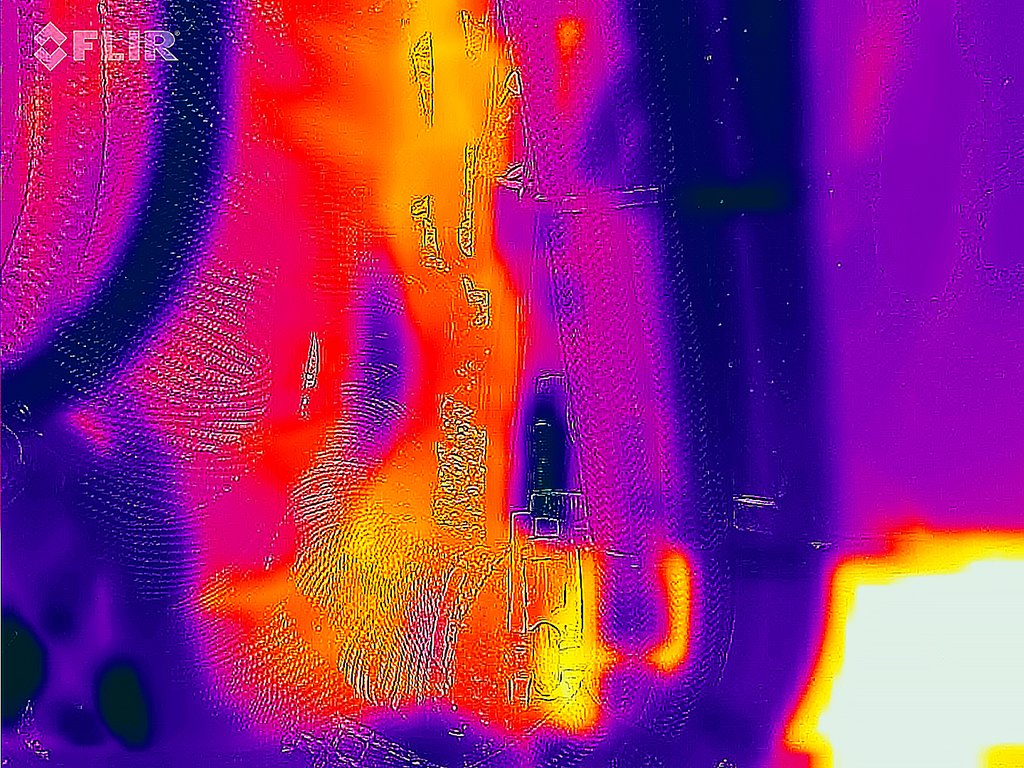

How hot does an unshielded turbo get underhood? Using the FLIR camera, this is the shot we took of the turbo after getting it up to temp. If you’re unfamiliar with FLIR (Forward Looking Infrared) imaging, the bright yellow/white areas are very high temperatures, while the purple/blue areas are lower temperatures.

Follow along as we install a Lava Exhaust Wrap and a Lava Turbo Shield to see the difference both make:

Follow along as we install a Lava Exhaust Wrap and a Lava Turbo Shield to see the difference both make:

- Our first step was to wrap the feed pipe to the turbo with LavaTM Wrap exhaust wrap. The other option for insulating this pipe would be Heatshield ArmorTM exhaust insulation, except in this case we didn’t have enough room in a couple of areas to allow for enough airspace so the Armor could insulate properly.

Above:

- The turbo’s pipe system was home-built by Kyle. To save money for use on other parts of the system, he built the bends in the pipe using pie-cut pieces. Functionally there is nothing wrong with this, but from an appearance standpoint some might find it less than attractive. Insulating the pipe with LavaTM Wrap will cover up the welds and have this pipe looking great.

Above:

3.To insulate the turbo exhaust pipes we’re using LavaTM Exhaust Wrap. Made from Heatshield’s specially-formulated volcanic rock fiber material, Lava Wrap has a maximum sustained temperature rating of 1200 degrees F, with an intermittent max of 2000 degrees. You can handle it with bare hands without getting itchy like with fiberglass-based materials. Even after multiple heat cycles, the Lava Wrap will remain flexible so you can remove it and reinstall it if necessary. The Lava fibers are also naturally chemical and acid resistant.

ABOVE:

- To keep the cut ends of LavaTM Wrap from fraying, an easy trick is to use some satin clear high-temp engine paint. This seals up the end of the wrap and since it’s rated for the same temperatures as the wrap itself, it won’t dissolve after heat cycling.

ABOVE:

5. When installing exhaust wrap, you want about a quarter- to half-inch of overlap of each loop. This makes sure the wrap will function properly to insulate the pipe, and also keep it tight and in place so it doesn’t unwind on you.

ABOVE:

6.The LavaTM Exhaust Wrap Installation Kit comes with everything you need for setting up, including plenty of Heatshield Products HP Thermal-TiesTM. Made of high-temp stainless steel they can handle 1800 degrees F continuous heat. To tighten them, use a pair of needle-nose pliers to tighten the tie by grabbing hold of the end and turning it, similar to peeling back the lid on a can of anchovies.

ABOVE:

- Here’s the finished result. No welds to be seen, and the carbon fiber look of the LavaTM Wrap will look great under the hood. But there’s one last thing to do before we reinstall the feed pipe.

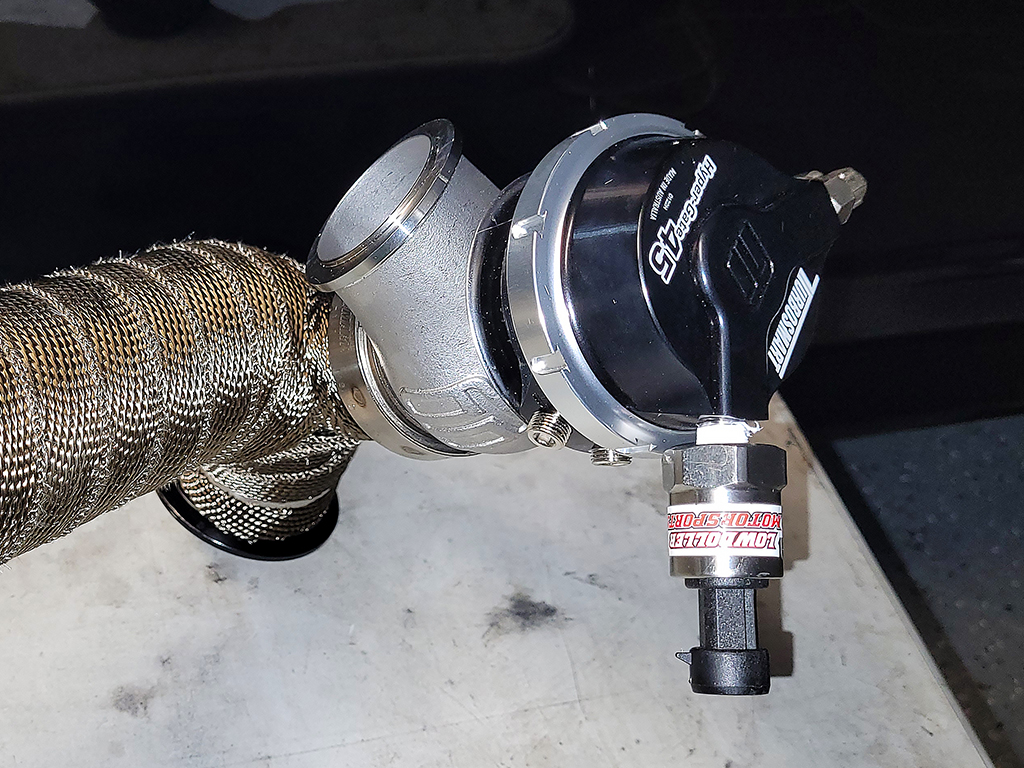

- Shielding the waste gate(s) from heat is often overlooked but can provide multiple benefits. First, shielding the wastegate and its diaphragm from heat helps the gate operate more consistently. Second, it also reduces heat wear on the wastegate diaphragm which increases diaphragm life and reduces the risk of premature failure.

ABOVE:

- LavaTM Wastegate Insulating Shield is made from the same specially-formulated volcanic rock fibers as LavaTM Wrap and LavaTM Turbo Shield. It’s easy to install and can be removed if necessary for turbo system maintenance. You can also see the Heatshield Products logo with the Made in USA flag. If you buy something that says its Heatshield Products but you don’t see an American flag on the part or in/on the package, then it’s not a genuine Heatshield Products item.

ABOVE:

10. LavaTM Wastegate Shield comes with Heatshield Products Power Anchor fastening system already installed. Power Anchors make installation and getting a tight fit much easier than a standard hook. They also allow for easier removal if necessary.

ABOVE:

- Almost looks too good to hide under a hood! With everything wrapped and insulated, the feed pipe is ready to be installed.

ABOVE:

- LavaTM Turbo Shield is Made in America from specially-formulated volcanic rock fibers. Multiple direct-fit sizes are available along with made-to-order shields if needed. It uses internal hems for a cleaner look and additional strength so Lava Turbo Shield won’t come apart after countless heat cycles. Internal hems also make for a better, tighter fit for more efficient insulating. Lava Turbo Shield is rated for 1800 degrees F continuous heat and up to 2200 degrees intermittent heat.

ABOVE:

- For securing LavaTM Turbo Shield on the turbo housing, HP Power AnchorsTM are built in to make installation (and removal) a piece of cake. A pair of HP SpringsTM made from 302 stainless steel are included to fasten the ends closed.

ABOVE:

- Another area where LavaTM Turbo Shield is superior to cheaper, lower quality turbo shields is fitment around the exhaust flange. Cheap turbo shields will often overlap the flange and require being forced back for the V-band clamp to install properly. It can also cause problems when removal is necessary. With Lava Turbo Shield you don’t have that problem,

ABOVE:

- With the feed and down pipe fully wrapped/insulated, having these pipes in the tight confines between engine and radiator/fan system won’t be causing any heat-related issues like killing the electric cooling fan motor because of heat exposure.

ABOVE:

- With everything reinstalled we fired the Mustang up and took a look through the FLIR camera to see how things looked from a temperature standpoint. Notice how with the LavaTM Turbo Shield installed you don’t see anymore white hot areas on the turbo housing, and very little bright orange. That’s how much insulting the turbo has cut down on the radiant heat generated by the turbo.

ABOVE:

- Here’s how things look now with the LavaTM Turbo Shield installed and not a big snail shell of cast iron next to the shiny compressor housing.

ABOVE:

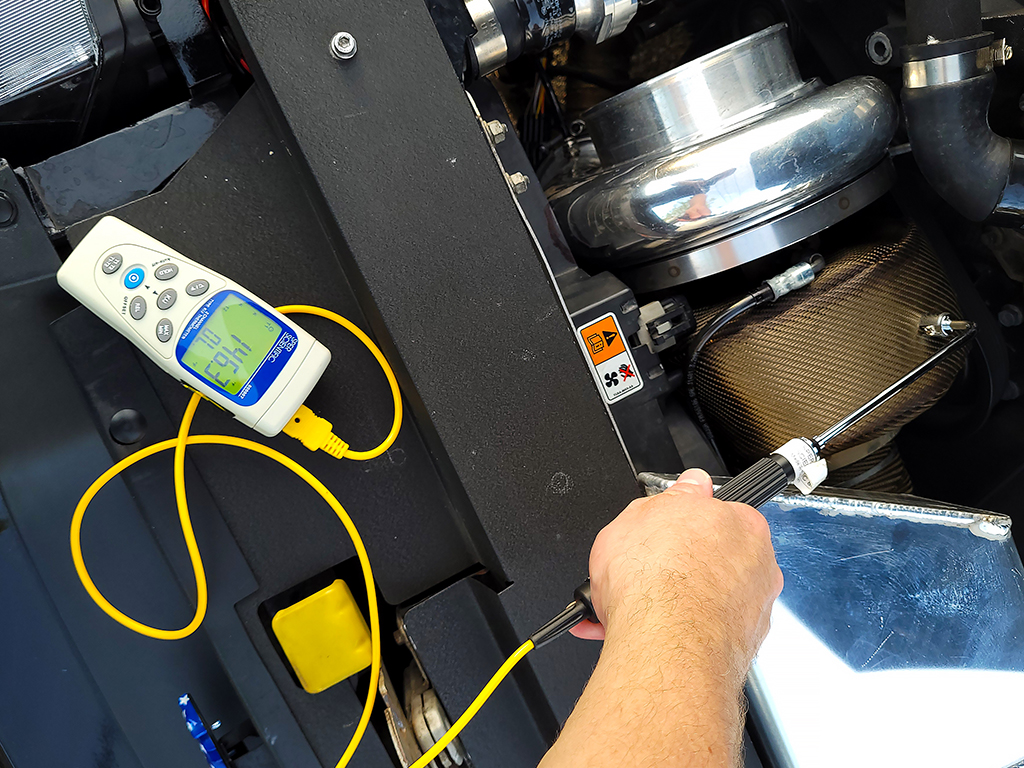

- Besides the FLIR image, we got out the temperature probes to see what the readings were through the LavaTM Heat Insulating Turbo Shield. First up was the contact probe.

ABOVE:

- With the contact probe we got a reading of 196.7 degrees F. An unshielded turbo housing typically measures from 300-450 degrees F or more depending on the size of the turbo and engine output.

ABOVE:

- With the laser temp gun, we got a reading of 149 degrees F from the turbo shield.

ABOVE:

- With the previous setup, the down pipe was so close to the plastic shroud of the factory electric fan it melted part of the shroud. The excessive radiant heat also killed the electric fan motor and necessitated its replacement. With LavaTM Wrap installed on the pipe, that won’t be happening again.

ABOVE:

- We left the shorty headers on the engine uninsulated deliberately. One, we wanted to know the difference between the insulated turbo pipe system and the headers. Two, we’ll be doing a separate before/after test using Header ArmorTM to show benefits of insulating your exhaust headers, and also how Header Armor is ideal in situations like our subject Mustang where space is tight and removal of the headers for installation is not desired unless absolutely necessary. The white-hot area in the image is the driver’s side header.

ABOVE:

- For further comparison between insulated and uninsulated, we checked the temperature of the wrapped turbo feed pipe just after the exhaust header.

ABOVE:

- We read through the wrap 209.8 degrees F with the direct-contact probe.

ABOVE:

- In the two photos you can see how things look to the normal eye, and how they look to the FLIR camera. FLIR really illustrates the difference between the insulated turbo feed and down pipes versus the uninsulated exhaust header.

Looking for a reliable and long-lasting turbo heat insulating turbo shield to manage heat within the turbine housing? Choose HeatShield Products – the best solution for automatic and performance market heat issues. You’ll find a range of quality, best performance automotive solutions for your needs, such as Turbo Wastegate Heat Shield, Industrial Stick, Turbo Guard, etc. For more info, visit our website, or you can write to us or contact us directly here