How Turbo Shields & Turbo Heat Blankets Can Improve Your Turbo Performance

Turbochargers are great ways to squeeze more horsepower out of an engine, but they also create a lot of heat in the engine compartment. Turbo heat blankets help control that heat and keep it where it belongs—inside the feed system creating maximum efficiency and performance. Proper turbo heat shields protect system components from damage and can improve the turbo performance of the cooling system, air conditioning, brakes, and beyond.

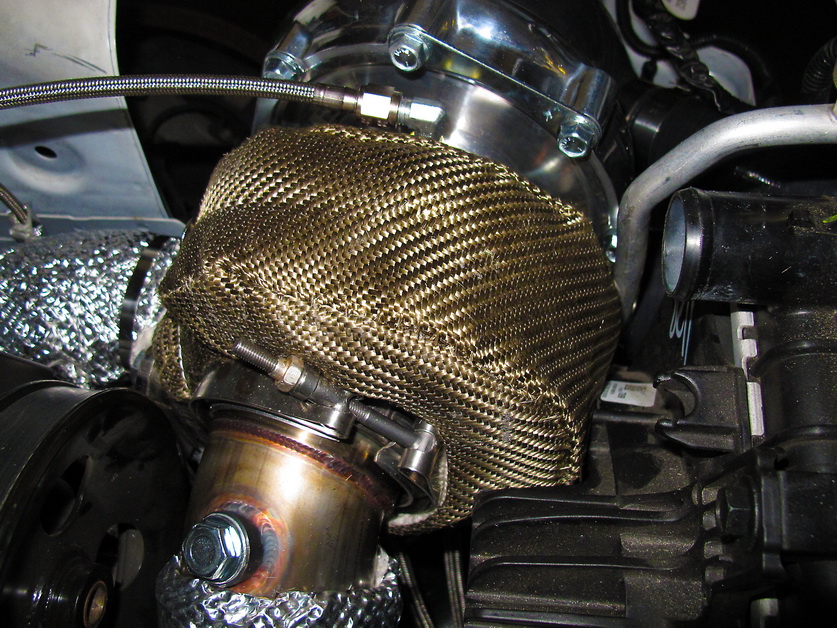

The exhaust side of the turbo sits in a cast iron housing that exhaust gas passes through, spinning the intake and compressing the air before it enters the engine. Just like the feed piping, keeping as much heat inside as possible is crucial for maximum turbo performance. That’s where a good, high-quality custom turbo heat shield or turbo blanket is important. A high-quality turbo shield will last through the many heat cycles it sees, while a cheap heat shield or turbo heat blanket will become brittle and lose effectiveness over time.

If you have an irregular turbo setup with a lot of customization, a Universal Turbo Heat Shield Kit may be the best turbo shield option for you. It includes everything you would need for properly insulating a turbo system, including a DIY turbo heat blanket that can be made to fit most turbochargers.

How Exhaust Feed Piping Can Help Turbo Performance

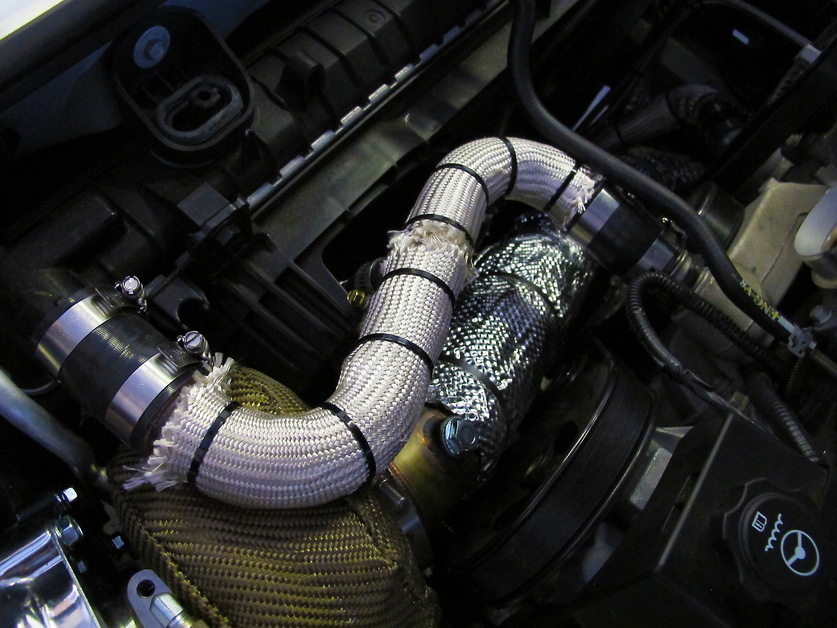

With most turbo heat blanket and turbo shield kits, the exhaust gas is tapped out of the engine just after the exhaust manifolds and is fed through piping into a single turbo or dual turbos. Keeping heat near the pipes is important so the exhaust gas temperature can remain as high as possible. High temps mean the exhaust gas velocity is as fast as possible improving turbo performance, reducing turbo lag, and increasing turbo boost.

While exhaust wrap is an option to use alongside your turbo heat blanket or turbo shield systems, installing it can be laborious and can get expensive. An effective option is Heatshield Armor. The material secures with HP Thermal Ties, is chemical- and water-resistant, and installs easily. Heatshield Armor can be sectioned to go around separate pieces of the pipe before they’re installed on the car making installation even simpler. Use it in conjunction with a turbo shield, increase your turbo boost, and ensure your car has the heat it needs in the places it needs it most.

Cooling, A/C, Brake, and Power Steering Lines

Shielding your A/C, brake, and power steering lines from increased ambient heat provides two benefits. First, it keeps rubber lines exposed to heat from degrading faster. Second, automotive heat shields applied to these critical fluid lines help keep the fluids inside protected. If your brake fluid gets too hot you may need to replace your brakes sooner rather than later. If the power steering fluid overheats the steering will start to go in and out and cause trouble. And if you’re A/C lines get hot your ride gets a lot less comfortable.

Some turbo shield and turbo heat blanket kits use sections of metal pipe to modify the cooling hoses so they work around the turbo location thus improving turbo performance. Protecting the lines helps your turbo shield work as effectively as possible, making sure the cooling system doesn’t have to work even harder to keep things at a proper operating temp. Plus, the HP Hose Sleeve won’t melt if it comes into direct contact with the heat source. For those A/C, power steering, and wiring lines that run near the feed piping and exhaust side of the turbo, our Thermaflect Sleeve can deflect any ambient heat.

The Intake Piping

New intake piping that comes with the turbo shield and blanket kit is metal and can soak in more ambient heat than factory plastic intake tubing. It’s easy to install and remove whenever necessary due to its high temp hook and loop fastener system.

Using these auto heat shields in conjunction with your turbo shield and turbo heat blankets helps increase turbo boost and improve turbo performance. Your vehicle will have the pickup and go you need in no time!