No matter which climate you live in, you will have observed that insulating your home keeps the warm air in and the cool air out—saving you money on your energy bills and keeping everyone more comfortable. In the same way, industrial pipe insulation is essential for ensuring the maximum efficiency of process pipes, hot pipes, and cryogenics in an industrial, or commercial setting. Read on to learn the benefits of industrial insulation and the piping insulation types offered at Heatshield Products.

Reasons to Use Industrial Pipe Insulation

Prevents Injury to Workers

As plant personnel go about their jobs, it’s imperative to make their work environment as safe as possible to prevent injuries and avoid downtime. That’s where different types of piping insulation come into play. The surface temperatures of hot and cold pipes in an industrial setting are particularly hazardous, as they could cause severe burns when touched accidentally or as part of routine maintenance. Applying industrial pipe insulation such as a pipe insulation wrap or sleeve to all of the pipework in your plant keeps the surfaces at a moderate temperature so that company personnel can go about their jobs safely and confidently.

Reduces Ambient Temperatures

In addition to resolving an immediate safety hazard, industrial pipe insulation can reduce the heat given off the pipework reducing ambient temperatures and preventing workers from becoming dehydrated and fatigued. By using industrial pipe insulation in the hottest areas of your power plant, such as the engine room, ambient temperatures can be reduced by as much as 70%—keeping personnel more comfortable and increasing productivity.

Increases Pipe Longevity

While industrial pipe insulation can help keep hot pipes hot and stop heat from leaking through, therefore increasing efficiency and safety, insulation can also help cold pipes, too. Industrial pipe insulation protects pipework exposed to outdoor temperatures from the cold and stabilizes the pipe’s temperature to prevent freezing. This, in turn, can stop pipes from bursting during the thaw of spring and save your company valuable time and money.

Ensures Consistent Process Temperatures

As we explain in the post “Why Industrial Insulation is Important,” choosing the right piping insulation types for thermal stability is crucial for ensuring the optimal performance of machinery and piping in any industrial setting. Pipelines that are experiencing thermal loss or gain will cause the engines to work harder and increase your greenhouse-gas emissions and power bill. An inefficient system will also reduce the total output of goods.

By covering piping with industrial pipe insulation, you can keep the heat and cold where they need to be and out of where they shouldn’t, while increasing the efficiency of the system and keeping temperatures stable. If you consider the role of heat in a furnace and cold in a freezer, you can understand why stable temperatures are a necessity!

Provides Passive Fire Protection

The materials used to make industrial pipe insulation—fiberglass, aluminum, and volcanic basalt—are non-corrosive and non-flammable. That means that installing these piping insulation types in your plant or commercial building will offer a certain amount of passive fire protection.

Reduces Vibration and Noise

Finally, industrial piping systems can generate a significant amount of noise due to the rattling of the pipes themselves and the movement of material through the system. While most piping insulation types are strictly for thermal insulation and don’t actually help with sound insulation, our Heatshield Armor can help with sound reduction. While primarily an insulation tool, our Heatshield Armor adds a physical barrier to prevent vibrating pipes from knocking against one another and may dampen the sound of contents passing through the pipes.

Pipe Insulation Types at Heatshield Products

The industrial pipe insulation types that we offer at Heatshield Products are made from three main materials: fiberglass, aluminum, and volcanic basalt. To accommodate several different pipe structures and sizes, we offer the following insulation products:

- Industrial Heat Shield Sleeving: Our Industrial Fire Sleeve Shield is made from braided fiberglass yarn with a silicone covering that is easy to clean. It can withstand continuous temperatures of up to 500°F. These sleeves are perfect for keeping heat and cold inside small-diameter pipes as well as shielding wires and cables from nearby heat sources.

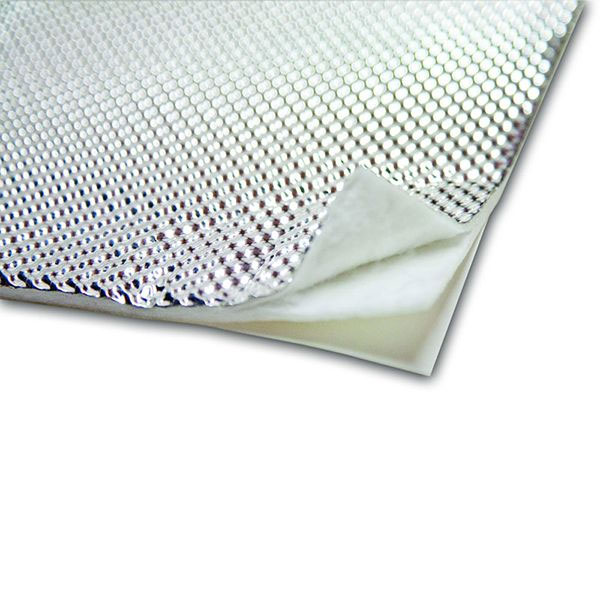

- Industrial Heat Shield Barriers: The mats and barriers in this collection are designed for use on large-diameter pipes as well as industrial ovens. Our ⅛” fiberglass industrial stick-on shield provides high temperature pipe insulation and can withstand temperatures up to 1100°F. It can also be secured to large pipes with our range of Industrial Heat Shield Tapes & Fasteners. Our industrial Lava Heat Shield Mat has a continuous operating temperature of 1200°F and requires a surface temperature of at least 65°F to be able to stick to the piping. These types of insulation can be used to shield radiant heat away from a cold pipe.

- Removable Genset Exhaust Jacket: This custom-made insulating jacket is perfect for large exhaust pipes as well as elbows, valves, and flanges that require a specific shape and size. We can make these industrial pipe insulation jackets with the fasteners of your choice, including:

- Lacing hooks

- Button studs

- D-rings

- Velcro flaps

- Heatshield Armor: This unique solution provides similar insulation protection to an industrial exhaust jacket. When used with a Power Anchor Kit, our heatshield armor can be configured as a removable insulation solution — great for parts that need regular maintenance or servicing! It may also be clamped on as a more permanent solution. Additionally, unlike a custom-made heat shield jacket that requires more lead time for creation, our heatshield armor is pre-cut for mass production. This minimizes lead time and allows you to cut and fit the product to your specific needs.

If you need a particular shape, size, or pipe insulation type, please get in touch for an individualized solution and a personalized quote. With the right measurements and/or samples of your old OEM piping insulation types, we can replace these at a great price with removable alternatives that you can reuse after cleaning and maintenance. All of the thermal products we sell at Heatshield Products are asbestos-free and made in America. Contact us for a quote, and explore our full range of industrial pipe insulation products today!