Outside of safety, a big area where modern cars hold superiority over classic cars is in the area of NVH (Noise, Vibration, and Harshness). Today’s vehicles boast much quieter interiors, allowing for more comfortable rides and quality listening experience for the sound system. The same improvements in sound damping and acoustic barrier technology benefiting modern cars can easily be applied to classic cars and trucks to improve ride quality and driving experience. Without ruining the classic looks and feel people enjoy about old cars.

The basic source of NVH is when a vehicle’s body panels are caused to vibrate. This comes from multiple sources such as exhaust and engine noise, noise and vibration created by the drivetrain, and road noise created by driving down the road. All of these sources cause a vehicle’s body panels to vibrate/resonate in some way at different frequencies. As metal is a highly conductive material, it easily transmits acoustic energy (meaning vibration and noise) into a vehicle’s interior.

Besides developing cutting edge thermal barriers and insulation to improve ride quality, Heatshield Products has come up with equally effective sound damping materials to significantly reduce NVH, but also without adding a large amount of dead weight to a vehicle, a major drawback to other acoustic damping materials on the market. The material for this particular test, db Armor, comes in at only 0.39-pounds per square foot of material.

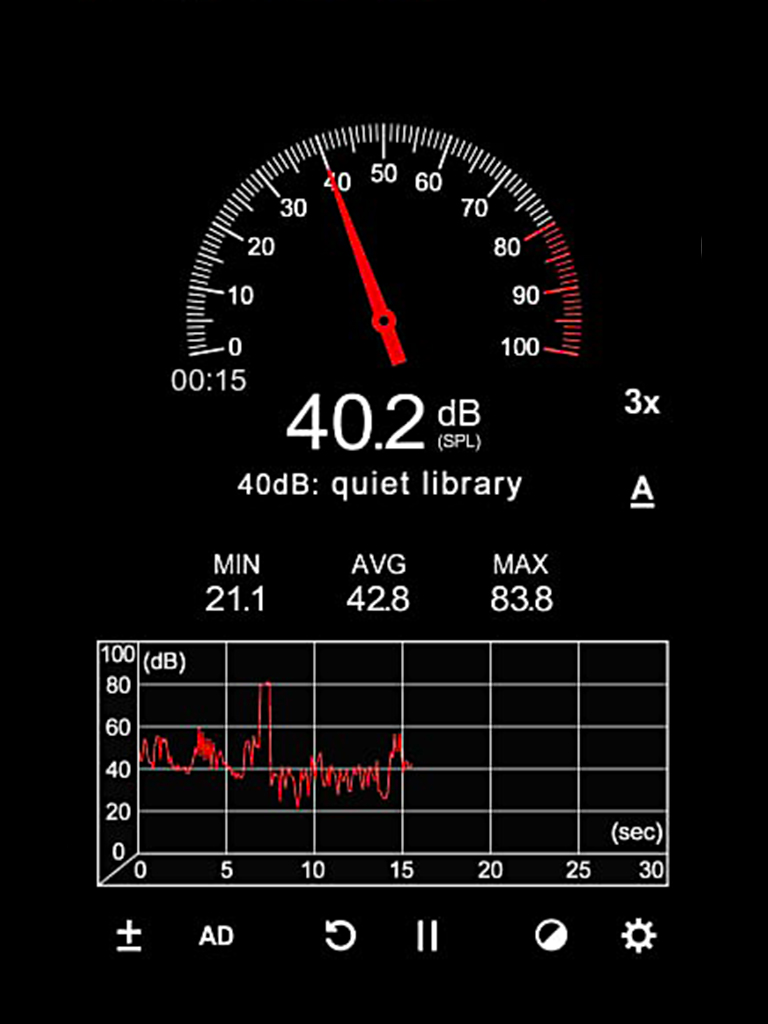

To show the difference db Armor makes, we set up simple test using a musical symbol and hammer. For measuring the acoustic difference, we downloaded a decibel meter app to our smartphone and set it up next to the symbol.

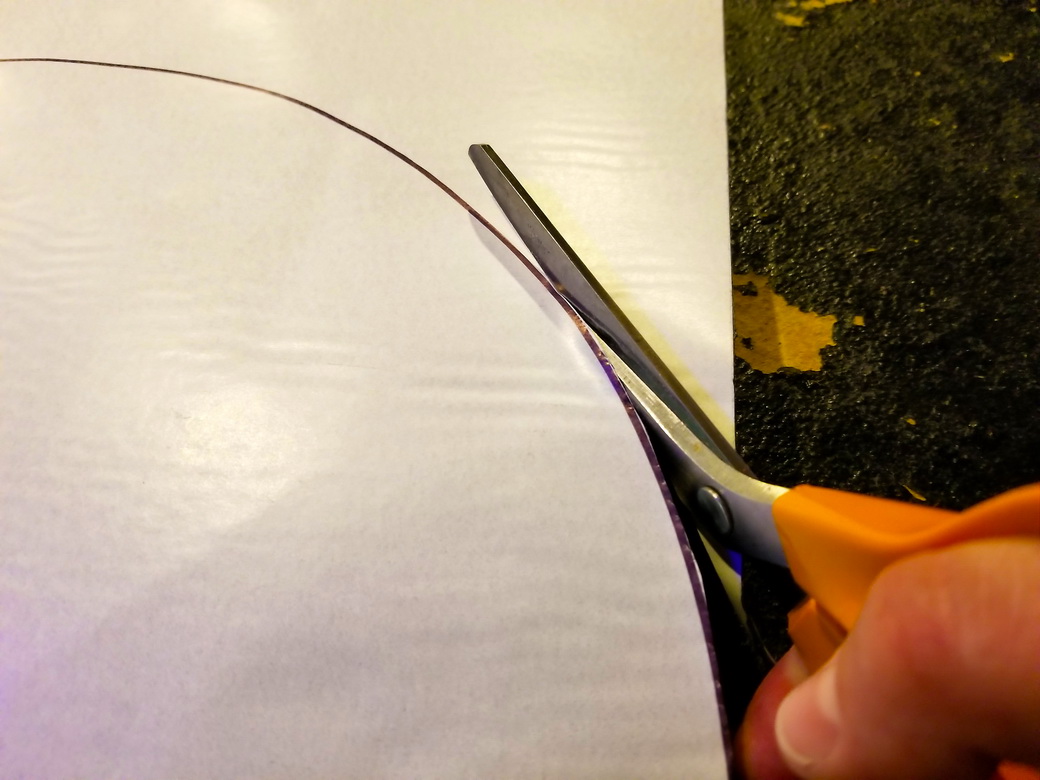

ABOVE: db Amor has multiple benefits. Besides being lightweight and highly effective, it is also easily cut and shaped to fit the surface it’s being installed on. For our test we just used a normal pair of scissors to cut the material. You also don’t need to do any special surface prep for db Armor’s adhesive backing to work properly.

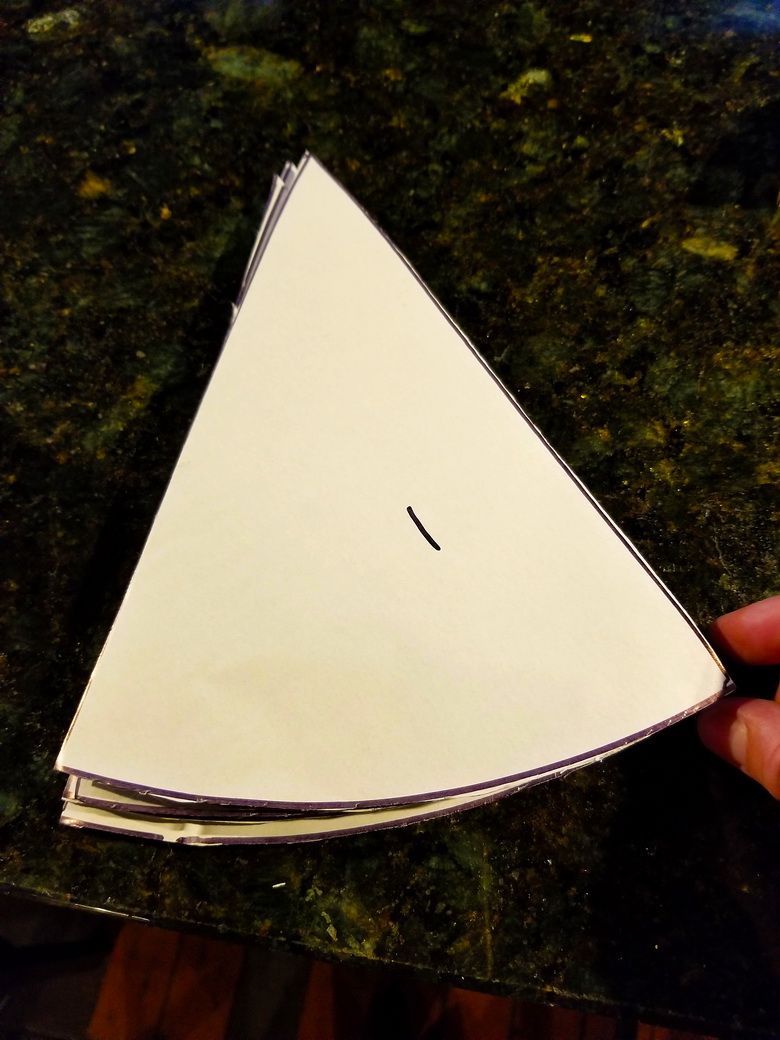

ABOVE: For our test, we cut the material into pie shaped pieces, to show how even a small piece of db Armor is effective in damping vibration. Each piece represents about 12.5 percent coverage of the symbol’s surface.

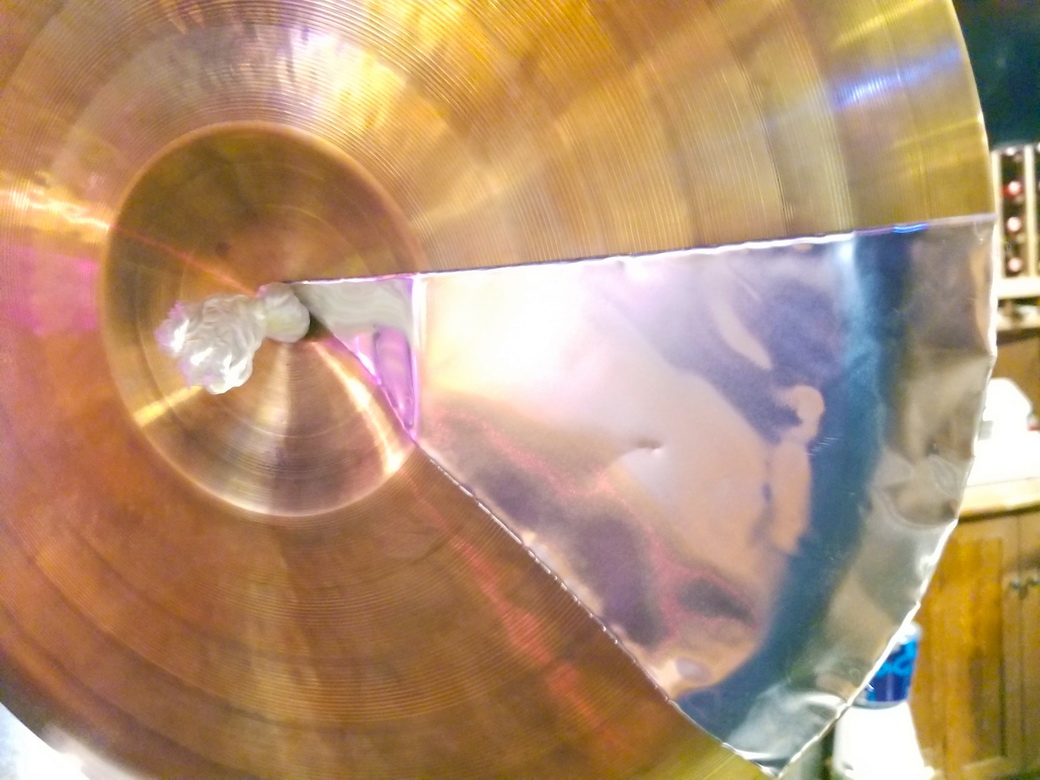

ABOVE: db Armor’s adhesive backing makes installation easy, with no special surface prep required. It’s also not as messy and difficult to work with as the adhesive backing on similar products.

ABOVE: After taking a baseline decibel reading of the symbol (78.8 decibels) we installed just one piece of db Armor on the symbol, covering about 12.5 percent of the symbol. After installation we went through the same procedure of striking the symbol with the decibel meter in the same exact position as before. This time we only measured 54.8 decibels, a decrease of 24 decibels. That’s a huge decrease thanks to just a small piece of sound damping material being installed.

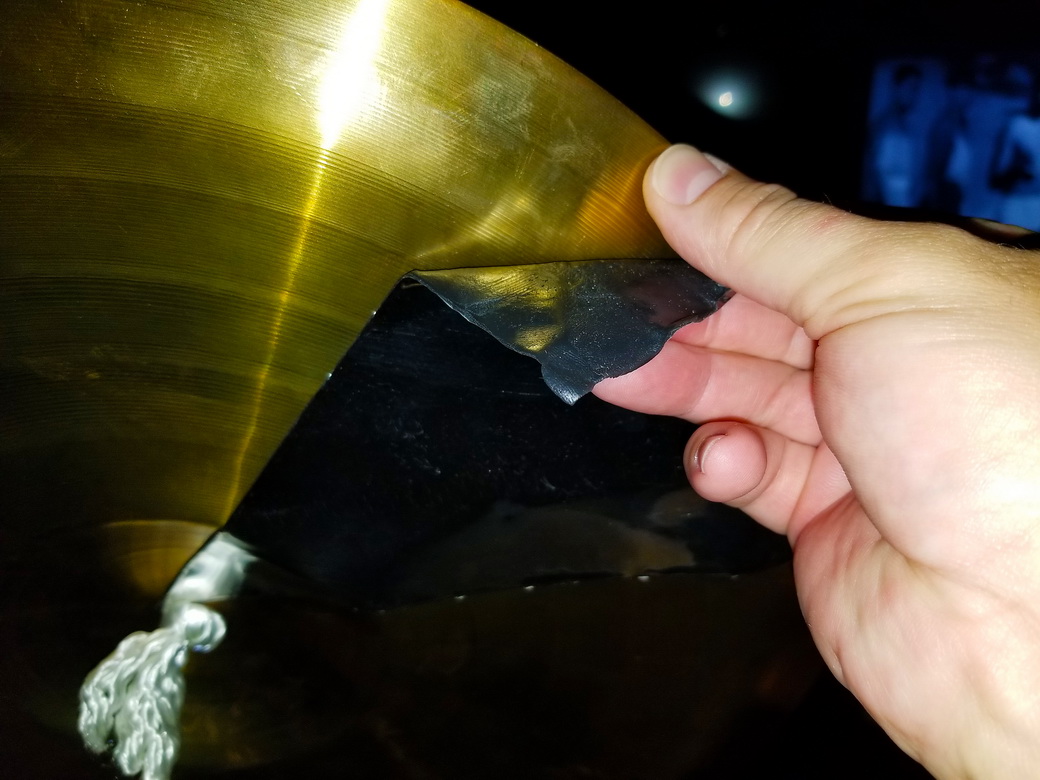

ABOVE: db Armor’s adhesive backing was engineered to not just stick to a surface, but also be removed easily and without ruining the material. This means if a user ever has to modify or repair a panel with db Armor installed, they can remove the material, do the necessary work, and reinstall db Armor as before.

ABOVE: For our test we downloaded a basic decibel meter app to our smartphone for use in the test.